Chemical Composition of wire (%)

| Cu | Sn | Mn | Si | Al | Pb | others | |

| Range | rest | ≤0.2 | ≤0.5 | ≤0.1 | 6.0-8.5 | — | ≤0.5 |

| Test | rest | 0.005 | 0.32 | 0.08 | 7.2 | 0.002 | — |

Mechanical properties of deposited metal

| Hardness of deposited metal

HB |

Yield strength Rp0.2 (Mpa) | Tensile strength Rm (Mpa) | Elongation ratio A (%) | Shield gas | ||||||

| 105 | 270 | 450 | 34 | 99.99%Ar | ||||||

Reference data of welding:

| MIG (DC+) | Welding wire size | 1.0mm | 1.2mm | 1.6mm |

| Welding current (A) | 160~280 | 180~300 | 200~350 | |

| Welding Voltage (V) | 18~28 | 20~30 | 22~34 | |

| TIG (DC-) | Welding wire size | 1.6-2.5mm | 2.5-4.0mm | 4.0-5.0mm |

| Welding current (A) | 150~250 | 200~320 | 220~400 |

Physical properties

| Melting temperature | Density(g/cm³) | Conductivity(%IACS) | ||

| 1030~1040 ℃ | 7.7 | 12~15 | ||

Welding Position: F, HF, V

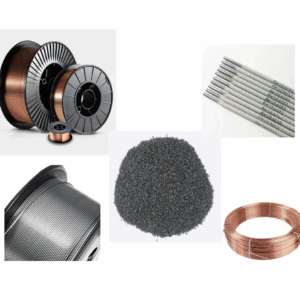

Welding methods: Mig DC+, Tig DC-